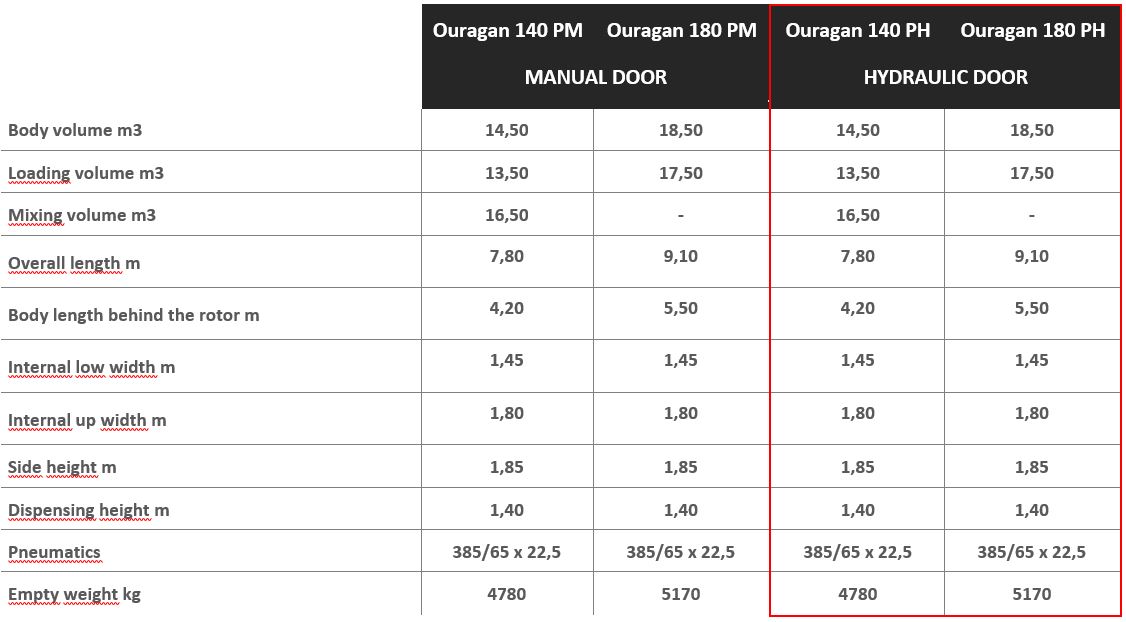

Ouragan 140 PM or PH

Rear door manual opening

Shredding – Dispensing – Mulching

3 shredding rotors mechanically driven by durable belt and automatic tightening

Fixed regulator comb

Driving of the 2 upper rotos by double chain

Turbine Ø 1600 mm composed of 8 removable paddles

Blower housing width 320 mm in anti abrasive steel (Brinel 430 hb 120 kg steel)

Visit trap door (blower)

2 speed gearbox (feeding 270 rpm – bedding 540 rpm) with free wheel

Lateral chute on the right hand side activated by 1 cylinder

Contra-rotating blade in chute issue

Dispense up to 18 m on the right with round and square bales

Floor conveyor

High strength Marine chain Ø 12, bars in removable rectangular tubes with manufactured ends ®

Driving of the floor conveyor by moto reductor oil bath, front and rear side with electric adjustable speed

Indicator of the floor conveyor rotation’s way

Conception – Safety

Removable bottom and sides

Dual floor with spring trap door for easy cleaning

Bolted housing

Road traffic

Linkage on piton

Parking brake and hydraulic brake

Light in accordance with the Highway code

Hydraulic kickstand with manual pump

1 fixed axle 100×100, 2 wheels 385/65×22,5

CE norms and DREAL homologation

Transmission

PTO transmission with protection, safety bowl machine side

Tractor equipment

PTO shaft for 540 rpm

Electrical plug 12v/3 pins for electric distributor

Electrical plug 12v/7 pins for light

Hydraulic distributor SE with direct return to the tank (speed regulator)

Minimum of flow 25l/mn

1 piton linkage

HYDRAULIC DOOR MODEL

Rear hydraulic door with 2 cylinders (1 DE) with electric distributor 3 functions (conveyor – chute – door)

Dual rear electric control 2 functions (conveyor – door)

Chutes and equipment

– Bedding and dispensing chute orientation front and rear 30° – on the right hand side chute

– Bedding chute orientation 300° for straw blower

– Hydraulic cylinder on the chute cap

– Hydraulic folding of the left mixing chute – not to exceed the machine height

Mechanical driving

– Multi-disc clutch with oil bath for mechanical driving of the rotor

Hydraulic

– Electric distributor 2 functions

– 1 additional function for electric distributor

– Hydraulic oil filter

– Hydraulic group 50l/min flow electric speed shifting (for tractor with lower flow than 30l/min)

Be carefull : compulsory to add the clutch ref 9582

Weighing

Weighing DG500 3 sensors, 48 programs, 18 components with horn (2 sensors on the axle and 1 on the drawbar)

Others

– Wheels 445/65 R22,5 width + 30 mm replacing the 385/65 R22,5 ones (the pair)

– Wheels 435/50 R19,5 width + 30 mm, height – 60 mm replacing the 385/65 R22,5 ones (the pair)

– Spare wheel 385/65 R22,5

– Mudguards the pair

– Speed shifting with electric control on blower box

– Atomizer

– Working light

– Revolving light

– Wide angle PTO transmission with protection machine side – Any PTO used will not be taken back neither exchanged